Thaum tshav kub kub hloov luam ntawvyog ib txoj kev, raws li ib qho tseem ceeb txuas nyob rau hauv tag nrho cov txheej txheem luam ntawv, nws yog ze ze rau lwm yam kev sib txuas, yuav ua li cas tswj kev ruaj ntseg ntawm cov txheej txheem yog ib qho tseem ceeb guarantee ntawm printing zoo. Hauv qab no, cia peb saib cov yam tseem ceeb uas cuam tshuam rau cov txheej txheem luam ntawv kub hloov pauv.

1. Thaum tshav kub kub luam ntawv taub hau

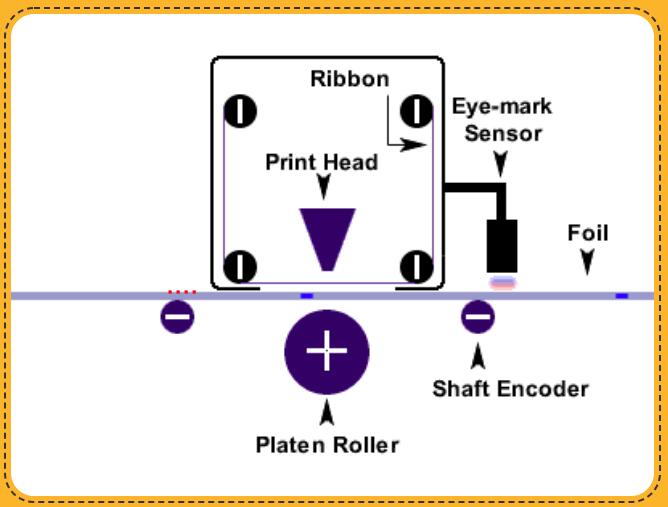

CovThaum tshav kub kub luam ntawvlub taub hau feem ntau muaj cov txheej txheem tiv thaiv zaj duab xis, hauv qab zaj duab xis tiv thaiv txheej thiab cov khoom cua sov.

Thaum tshav kub kub hloov luam ntawv ceev nyob ntawm lub sij hawm xav tau rau txhua kab ntawv. Yog li ntawd, lub tshav kub hloov lub taub hau thiab hloov daim ntawv yuav tsum muaj kev ua tau zoo, thiaj li hais tias lub tshav kub generated los ntawm cov cua sov lub sij hawm sai sai dhau los ntawm cov txheej txheem tiv thaiv, hloov daim ntawv substrate thiab qhov sib txawv thaum kawg mus rau lub substrate nto, thiaj li yuav xyuas kom meej tias tus number case muaj. txaus hloov sijhawm.

2. Tus cwj mem

Qhov sib xyaw ntawm cov tshuab luam ntawv kub hloov pauv feem ntau yog xim xim (xim lossis xim), siv quav ciab thiab roj peb ntu.

Thaum luam ntawv, cov viscosity ntawm cov number case sib txawv yog ncaj qha ntsig txog cov cua kub kub, thiab cov cua kub yuav tsum nruj me ntsis tswj nrog cov viscosity ntawm number case.

3. Hloov daim ntawv

Kev ua haujlwm zoo thermal vim qhov kev hloov pauv yuav tsum ua kom tiav los ntawm kev kub siab, yog li cov khoom siv ntawm cov ntawv hloov pauv yuav tsum muaj peev xwm tiv taus qhov cuam tshuam ntawm kev hloov pauv kub, cov khoom txuas ntxiv tsis hloov pauv. Feem ntau, thermal kev ua tau zoo ntawm cov khoom siv ntawm cov ntawv thermal hloov pauv, uas tuaj yeem cuam tshuam los ntawm cov hauv qab no:

ib. Qhov qis dua thermal tsis kam thiab thinner ntawm substrate, qhov zoo dua qhov kev hloov hluav taws xob zoo dua.

b. Lub smoother ntawm lub substrate nto, qhov zoo dua thermal kev ua tau zoo.

c. Thaum tshav kub kub kub stamping kub yog feem ntau txog 300 ℃, cov khoom siv hauv paus yuav tsum muaj peev xwm xyuas kom meej tias qhov kev ua haujlwm tseem ceeb tsis hloov ntawm qhov kub no.

4. Substratesnto

Qhov kev paub qhia tau hais tias me ntsis ntawm qhov ntxhib saum npoo ntawm cov ntawv luam tawm yog qhov zoo, qhov no yog qhov pom tseeb ntawm kev hloov hluav taws xob. Vim tias qhov ntxhib ntawm lub substrate qhia tau hais tias lub substrate muaj lub zog loj dua, tus number case ntawm daim ntawv hloov pauv tuaj yeem hloov mus rau substrate zoo heev, piv nrog rau qib zoo thiab kev txiav txim; Tab sis ntxhib dhau lawm yuav cuam tshuam rau kev hloov pauv ntawm tus cwj mem, tsis zoo rau kev ua tiav ntawm cov txheej txheem luam ntawv.

Clikc txuas hauv qab no, koj tuaj yeem pom qhov tsim nyogcov ntawv sau ua kom sovkoj xav tau.

https://www.colorpglobal.com/heat-transfer-labels-product/

Post lub sij hawm: Jun-20-2022